Materials & Manufacturing

The physical basis for nanomaterials research

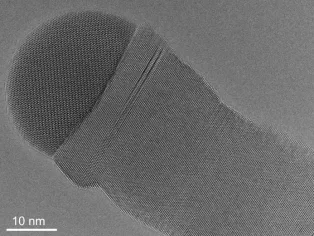

We develop the structures that constitute the physical basis for all nanomaterials research, as well as for future nanotechnology and industrial production. We explore both physical and chemical synthesis methods for generating nanoparticles, nanowires, and nano-layers. We further aim to relate atomic structure and properties of materials and understand when and how nanostructures form.

On this page:

- Subareas within Materials & Manufacturing

- Publications

- Recent PhD-theses relevant to Materials & Manufacturing

- Key faculty in Materials & Manufacturing

Subareas within Materials & Manufacturing

- Compound material synthesis and integration

Exploring new materials from a foundation in III-V semiconductors - Nanoparticle synthesis and assembly

Semiconducting, magnetic or catalytic nanoparticles as building blocks. - Nanofabrication and industrial production

Novel nanofabrication methods, and integrating nano in industrial production.

Publications

- Alfred Larsson, The Formation and Breakdown of Passive Film on Ni Alloys: in situ synchrotron studies, PhD thesis, Faculty of Science, Lund University 2023.

- Giuseppe Abbondanza, Ordered arrays of low-dimensional Au and Pd, PhD thesis, Faculty of Science, Lund University 2023.

- Heera Menon, Infrared Photodetectors based on InSb and InAs Nanostructures via Heterogeneous Integration-Rapid Melt Growth and Template Assisted Selective Epitaxy, PhD thesis, Faculty of Engineering, Lund University 2023

- Jennifer Gilbert, Unravelling the structure and dynamics of lipid nanoparticles for biomolecule delivery, PhD thesis, Faculty of Science, Lund University 2023.

- Klara Suchan, Life and Death of Mixed Metal Halide Perovskites: Mechanism and Consequences of Light Induced Halide Segregation in MAPb(I,Br)3, PhD thesis, Faculty of Science, Lund University 2023.

- Markus Snellman, Aerosol Synthesis and Characterization of Heterogeneous Bimetallic Nanoparticles, PhD thesis, Faculty of Engineering, Lund University 2023

- Sandra Benter, Adventures of III-V Semiconductor Surfaces, PhD thesis, Faculty of Science, Lund University 2023.

- Sara Franzén, Design and development of solid-state nanostructures for catalysis, PhD thesis, Faculty of Engineering, Lund University 2023.

- Susanna Hammarberg, Strain Mapping of Single Nanowires using Nano X-ray Diffraction, PhD thesis, Faculty of Science, Lund University 2023.

- Giulio D'Acunto, Reaction Mechanisms and Dynamics in the Early Stage of High-κ Oxide Atomic Layer Deposition: Investigations by In Situ and Operando X-ray Photoemission Spectroscopy, PhD thesis, Faculty of Science, Lund University 2022.

- Lasse Södergren, InGaAs Nanowire and Quantum Well Devices, PhD thesis, Faculty of Engineering, Lund University 2022.

- Lukas Hrachowina, Growth and Characterization of Tandem-Junction Photovoltaic Nanowires, PhD thesis, Faculty of Engineering, Lund University 2022.

- Virginia Boix, Graphene: Applications in Surface Science Studies, PhD thesis, Faculty of Science, Lund University 2022.

- Yen-Po Liu, Surfaces and interfaces of low dimensional III-V semiconductor devices, PhD thesis, Faculty of Science, Lund University 2022

- Yi Liu, Surface modification of III-V nanostructures studied by low-temperature scanning tunneling microscopy, PhD thesis, Faculty of Science, Lund University 2022

- Anders Gustafsson

- Anders Mikkelsen

- Arkady Yartsev

- Aylin Ahadi

- Bo Monemar

- Dmitry Baranov

- Donatas Zigmantas

- Edvin Lundgren

- Elizabeth Blackburn

- Erik Lind

- Eva Unger

- Håkan Pettersson

- Ivan Maximov

- Ivan Scheblykin

- Jan Knudsen

- Jan-Eric Ståhl

- Jens Uhlig

- Jesper Wallentin

- Joachim Schnadt

- Jonas Johansson

- Jonas Ohlsson

- Karen Edler

- Kenneth Wärnmark

- Kimberly Thelander

- Knut Deppert

- Lars Montelius

- Lars Samuelson

- Lars-Erik Wernersson

- Lindsay Merte

- Magnus Borgström

- Maning Liu

- Maria Messing

- Maria Sandsten

- Martin Ek Rosén

- Martin Magnusson

- Matias Kagias

- Mats-Erik Pistol

- Mattias Borg

- Petter Persson

- Rainer Timm

- Rasmus Westerström

- Reine Wallenberg

- Sara Blomberg

- Sven Lidin

- Tönu Pullerits

- Vanya Darakchieva

- Volodymyr Bushlya

Topical meetings Materials and Manufacturing

Topic: Materials & Manufacturing

Date: Thursdays, odd weeks

Time: 09:00–10:00

Place: k-space

Organizer: Martin Ek Rosén, Mattias Borg & Erik van Loon

Coordinators Materials & Manufacturing

People in Materials & Manufacturing

People on the Materials & Manufacturing e-mailing list (PDF, opens in LU Box)

WISE: Wallenberg Initiative Material Science for Sustainability

The Wallenberg Initiative Materials Science for Sustainability (WISE) is the largest-ever investment in materials science in Sweden and will encompass major efforts at six of Sweden’s leading universities over the course of (at least) 10 years.